AEON Co., Ltd. (AEON), AEON KYUSHU Co., Ltd. (AEON KYUSHU), AEON GLOBAL SCM Co., Ltd. (AEON GLOBAL SCM), and Commercial Japan Partnership Technologies Corporation (CJPT) will implement initiatives seeking to address social issues faced by the logistics industry and contribute to carbon neutrality at the new logistics center AEON Fukuoka XD.

AEON has been working on improving efficiency in each stage of distribution, from procurement to sales, with the aim of optimizing logistics. CJPT has been focusing on two pillars: logistics efficiency which it believes will not only solve logistics issues but also lead to immediate carbon neutrality and vehicle electrification.

AEON and CJPT started collaborating at AEON Global SCM’s South Osaka RDC*2 from April 2021 as Phase 1. Combining the retail logistics expertise built up by AEON and the philosophy of TPS (Toyota Production System), the companies aimed to visualize and streamline the flow of goods, achieving improved loading efficiency through work improvement in the logistics center and optimal delivery utilizing real-time data. As a result, they achieved approximately 10% efficiency improvement in total truck mileage and a 10% reduction in CO2 emissions. Starting from September 2022 as Phase 2, in collaboration with AEON KYUSHU, the scope of activities has further expanded to include wholesalers and suppliers. This expansion has resulted in the streamlining of the entire supply chain from upstream to downstream through cross-industry initiatives.

As part of Phase 3, AEON and CJPT will strive to enhance the effectiveness of logistics efficiency by consolidating these initiatives at the new logistics center, AEON Fukuoka XD, which will commence full operation starting on July 24, 2024.Furthermore, by promoting “vehicle electrification,” the companies aim to address logistics problems and achieve carbon neutrality, targeting a 35% reduction in CO2 emissions by 2030*3. Specifically, “logistics operations automation” will be integrated into efforts to reduce overall travel distance through improvements both in operations within the logistics center and in optimal delivery. This will help reduce workload and enhance productivity. In addition, the companies will actively pursue the reduction of CO2 emissions through the introduction of fuel cell (FC) small trucks and other environmentally friendly vehicle technologies.

Moving forward, the companies will expand the initiatives throughout the entire supply chain, improving efficiency in procurement logistics through data integration with suppliers and utilizing double-trailer trucks and collaborative transportation for long-haul logistics. AEON and CJPT will take on the challenge of achieving carbon neutrality and addressing nationwide logistics problems, thereby contributing to society’s overall logistics challenges.

Concrete initiatives based on the new logistics center “AEON Fukuoka XD”

| Categories | Initiatives | Target | Reduction in CO2 emissions |

|---|---|---|---|

| Logistics Efficiency Improvement | Efficiency pursuit through integration of stores and logistics based on TPS philosophy

| 10% reduction in total mileage | ▲10% |

Efficiency improvement through data/automation technology in logistics

| 10% reduction in total mileage 30% increase in shipping capacity | ▲10% | |

| Vehicle Electrification | Reduction of CO2 emissions through environmental and vehicle technologies

| 15% of all vehicles | ▲15% |

| Contribution to Local Communities | Resolution of logistics problems

| ||

| *1 | Cross Dock = A logistics facility with the function of temporarily receiving and quickly delivering goods to the appropriate location. |

|---|---|

| *2 | Regional Distribution Center = A logistics facility that stores fast-moving goods and supplies them to stores in the designated area through a cross-dock center in the designated area. |

| *3 | Submitted on October 22, 2021―Japan’s NDC (³Ô¹ÏÍøÕ¾ly Determined Contribution) as determined by the national government. |

- Name

- AEON Fukuoka XD

- Location

- 1-1-4 Minato Kashii, Higashi-ku, Fukuoka City, Fukuoka, Japan, T-LOGI Fukuoka Island City 1F-2F

- Leased Area

- 41,335.80 square meters

Improvement of work efficiency by incorporating TPS (Toyota Production System) philosophy

AEON and CJPT collaborating at the worksite

AEON and CJPT collaborating at the worksite Efficiency improvement case

Efficiency improvement case

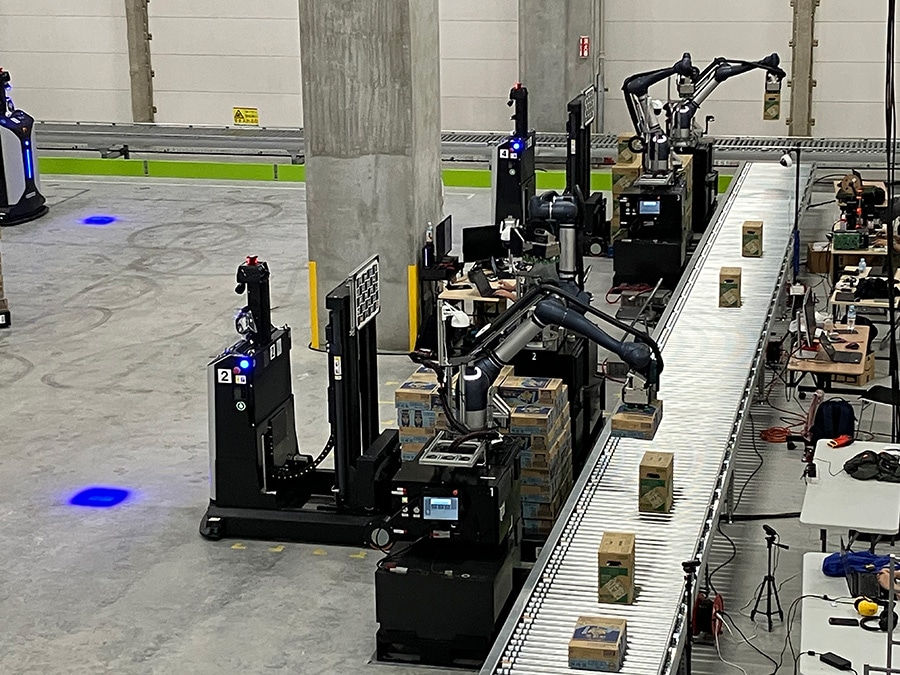

AI remote Depalletizing arm robot

AI remote Depalletizing arm robotRemote unmanned forklift AGF

Next-generation AGV (Automated Guided Vehicle) transportation system

Next-generation AGV (Automated Guided Vehicle) transportation system

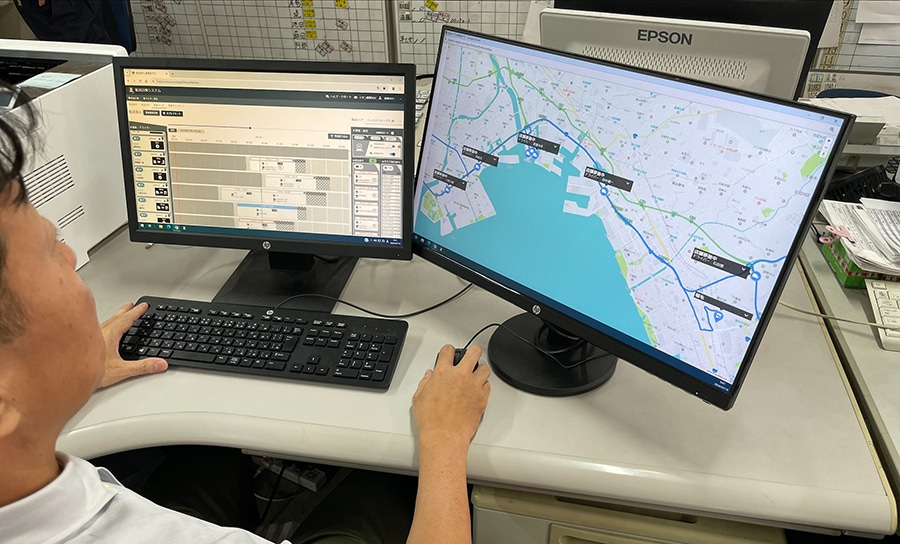

Optimal delivery planning system (E-TOSS*4) utilizing connected technology and real-time data

Utilizing E-TOSS for dispatching

Utilizing E-TOSS for dispatching Image of Dispatch planning

Image of Dispatch planning

| *4 |

|

|---|

- Hydrogen-powered fuel cell vehicles emit zero CO2 during operation

Utilizing the Fukuoka Prefecture Fuel Cell Truck Introduction Promotion Project subsidy

“Achieving zero, and adding new value beyond it”

As part of efforts to pass our beautiful “³Ô¹ÏÍøÕ¾ Planet” to the next generation, Toyota has identified and is helping to solve issues faced by individuals and overall society, which Toyota calls “Achieving Zero,” hoping to help reduce the negative impacts caused by these issues to people and the environment to zero. Additionally, Toyota is also looking “Beyond Zero” to create and provide greater value by continuing to diligently seek ways to improve lives and society for the future.

- About Beyond Zero

Toyota Motor Corporation works to develop and manufacture innovative, safe and high-quality products and services that create happiness by providing mobility for all. We believe that true achievement comes from supporting our customers, partners, employees, and the communities in which we operate. Since our founding over 80 years ago in 1937, we have applied our Guiding Principles in pursuit of a safer, greener and more inclusive society. Today, as we transform into a mobility company developing connected, automated, shared and electrified technologies, we also remain true to our Guiding Principles and many of the United Nations’ Sustainable Development Goals to help realize an ever-better world, where everyone is free to move.

- SDGs Initiatives