The world-first 3D printed chest reconstruction implant that has changed the life of a young medical student is the outcome of years of research by QUT Distinguished Professor Dietmar W. Hutmacher, an internationally recognised scientist who pioneered the use of patient-specific 3D printed scaffolds to repair bone and other tissue, and his team.

- 3D printed implant utilised technologies developed by Professor Dietmar Hutmacher and team

- Implant corrects the birth defect known as funnel chest

- The implant used 90 per cent of the patient’s own tissue

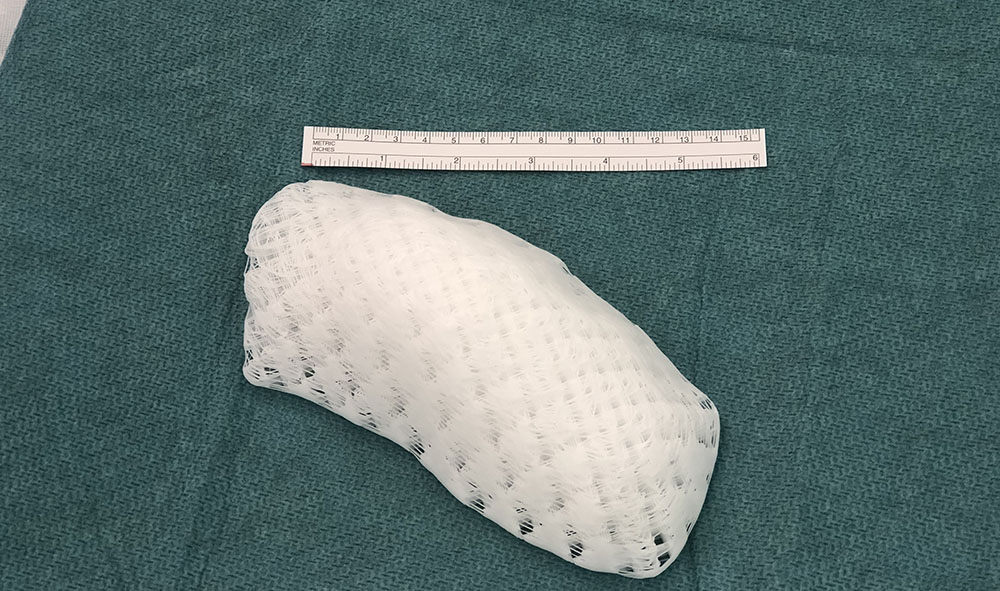

The implant has corrected a birth defect called funnel or sunken chest whereby the ribs and sternum grow inwards giving a concave appearance.

, the director of the in QUT’s Centre for Biomedical Technologies said the implant was made from porous, biodegradable material.

“The implant was made to fit precisely over the chest deformity to allow the patient’s own blood vessels and fat tissue to grow into the implant to create a lasting normal shaped chest,” Professor Hutmacher (pictured above with Dr Matthew Cheng) said.

“The implant had to be flexible as the chest is in constant movement and so it had to have the ability to change shape without breaking.

“The soft tissue scaffold contained no ceramic additives that we use for rigid bone scaffolds.

“Our research with Dr Matthew Cheng over the past five years has shown that an implant injected with the patient’s own fat at the time of implantation would give the best chance of success.”

The surgery at Princess Alexandra was performed by Dr Michael Wagels who has collaborated closely with Professor Hutmacher for many years.

“An important part of the surgery was injecting the scaffold with the patient’s own fat at the time of implant insertion to commence the reconstruction/regeneration of the highly porous scaffold with more than 90 per cent of her own tissue,” Dr Wagels said.

Dr Wagels, an Adjunct Professor with QUT, also performed the world-first reconstruction of the long bone on a Queensland man in 2017 with a patient-specific 3D printed scaffold using QUT technology and last year a 3D-printed skull implant to replace and infected section of the skull.

The interdisciplinary team effort which transformed the young patient’s life involved extensive planning to design and additively biomanufacture the implant with the support of clinicians at Princess Alexandra Hospital, Translational Research Institute (TRI), Australian Centre for Complex Integrated Surgical Solutions (ACCISS), ARC ITTC in Additive Biomanufacturing and the printing of the patient-specific scaffold by German company BellaSeno GmbH.