ANSTO’s Australian Synchrotron is among the organisations that have received an Australian Research Council Linkage Project grant for research on an advanced battery system for stationary energy storage.

Water-based iron flow batteries, being developed by University of Queensland researchers with industry partner Energy Storage Industries Asia Pacific, use non-toxic iron chloride as the electrolyte and are re-chargeable and suitable for large grid scale storage.

They offer the potential for clean, reliable and cost-effective long duration energy.

During the discharge of an iron flow battery, iron (III) chloride is reduced to iron (II) chloride at the positive electrode. At the negative electrode, the metallic iron is dissolves into the electrolyte as iron (II) chloride. The processes are reversed during battery charging,

An ARC Fellow and Group leader at the Australian Institute for Bioengineering and Nanotechnology (UQ) Dr Bin Luo, Prof Ian Gentile of School of Chemistry and Molecular Biosciences (UQ) and Research fellow Dr Masud Rana of UQ will continue work to overcome the main obstacle for large scale commercial deployment. There is a low round-trip energy efficiency caused by a competitive side reaction that occurs at the negative electrode during battery charging.

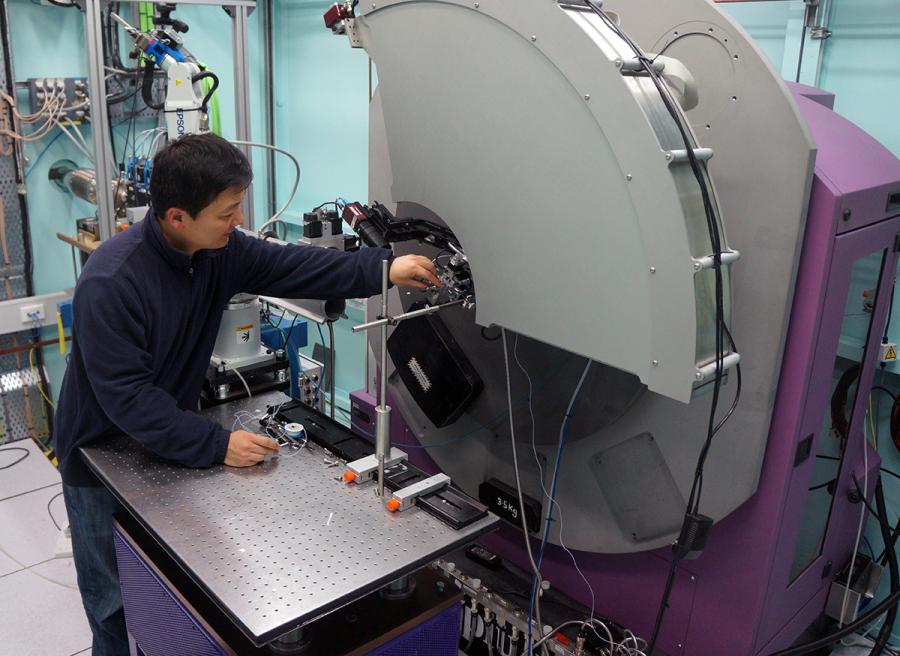

Principal beamline scientist Dr Qinfen Gu is a partner investigator who will support the project and help with experimental design, operando set-up development, flow battery testing and data analysis using the at the Australian Synchrotron.

“The powder diffraction beamline is useful in determining how structural modifications impact function. The performance of innovative new materials can also be tested on an operating battery at the Australian Synchrotron, where we support a great range of battery research,” said Dr Gu.

The project will address the low energy efficiency of the system by engineering the negative electrode-electrolyte interface with functional materials to improve battery performance and reduce costs.

The goals of the project are design iron electrodes with functional interface layers; demonstrate the iron flow battery technology at the lab scale; undertake a pilot scale test of the technology for commercial applications and understand the effect of the functional interface layer on the iron plating process and battery performance.

With the linkage grant funding, the team intends to produce new materials and methods for advanced battery technology and Australian manufacturing and support the national priority of net-zero carbon emissions by 2050.