Public display shows scans and images of microplastics in Melbourne’s Yarra River, image supplied by DFM

Swinburne design students have created concepts to reduce tyre dust levels and micro-plastics found in our waterways.

Master of Design student Kanika Shah, Master of Design Strategy and Innovation student Jeannie Foo and Bachelor of Design (Interior Architecture) (Honours) student Jing Tan in the at Design Factory Melbourne (DFM), developed the concepts in a bid to improve the quality of Australian water ways.

The connects and the (SDGs). A³ is a DFM initiative, building on earlier Innovation (CBI) pilots at Design Factory node , focused on applying design innovation to develop outcomes that connect technology with societal needs in a tangible way.

Over six months, international student teams explored design applications for future scenarios that unite CERN Tech and SDGs. For the 2018-2019 CBI A3 program, Design Factory, they focused on SDG 6: Clean Water and Sanitation and SDG 14: Life below Water.

The CBI A3 program is offered to partner universities in the (DFGN). Teams from Melbourne, Porto (Portugal), New York (USA) and Mannheim (Germany) proposed ideas for their local regions in the years 2020, 2025 and 2030. Students met at IdeaSquare at CERN in Geneva for a two-week intensive program where they connected with experts.

Four global student teams and supporting academics at CERN, Geneva, image supplied by DFM

Design Factory students at IdeaSquare CERN, image supplied by DFM

DFM students chose to focus on the second largest global source of microplastic, tyre dust, which contains over 140 chemicals and can be toxic when ingested. To combat tyre dust pollution for the year 2020, students Shah and Foo propose a way to collect data, raise awareness, build support and put pressure on tyre manufacturers to find environmentally friendly solutions to the problem.

Scanley, a scanner and imaging machine shows microplastics hidden in water. Using CERN’s Medipix technology it detects the chemical composition of materials in water samples. Installed in Melbourne, along the Yarra River, Scanley educates the public, providing information about microplastic contamination.

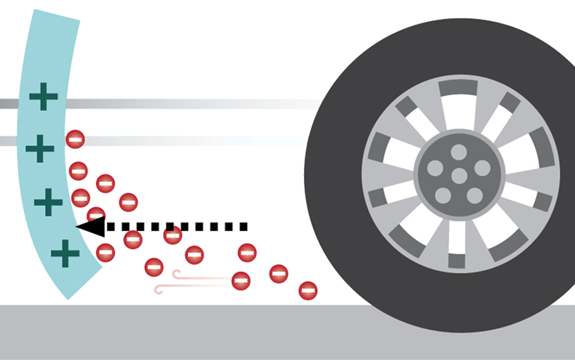

For 2025, the second design concept attracts and collects airborne tyre dust, facilitated by an electrostatic plate installed behind the wheels of electric vehicles, with a vacuum suction device and collection chamber under a vehicle.

Diagram demonstrating electrostatic charge attracting tyre dust, image supplied by DFM

For the year 2030 the team propose an automated curbside cleaning robot. The smart robot vacuum cleaner collects, sorts and disposes of tyre dust, small particles and debris before they reach waterways.

Curbside cleaning robot collecting dust and debris, image supplied by DFM

The robot converts waste to power and generates carbon black. Utilising data sources, it targets areas where rainfall is predicted and shares weather information with passers-by.

Tan, an interior design honours student, explored other ways to combat and increase awareness of tyre dust on urban environments. Her concept attracts tyre dust by using an electrostatic ring retrofitted to the undercarriage of Melbourne’s E-class trams.

Window in tram floor shows vacuum process of collecting tyre dust, image supplied by DFM

Utilising power emitted by a tram, the ring activates as the tram moves, and attracts the dust. When the tram stops, CERN vacuum systems pull contents into a central storage tank. Passengers can watch this process through a window in the tram floor, raising awareness about micro-plastics and tyre dust.