Deakin textile and fibre scientists have discovered how to turn plant waste into a biodegradable material that could replace environmentally-damaging plastics such as those used for packaging and other throwaway items.

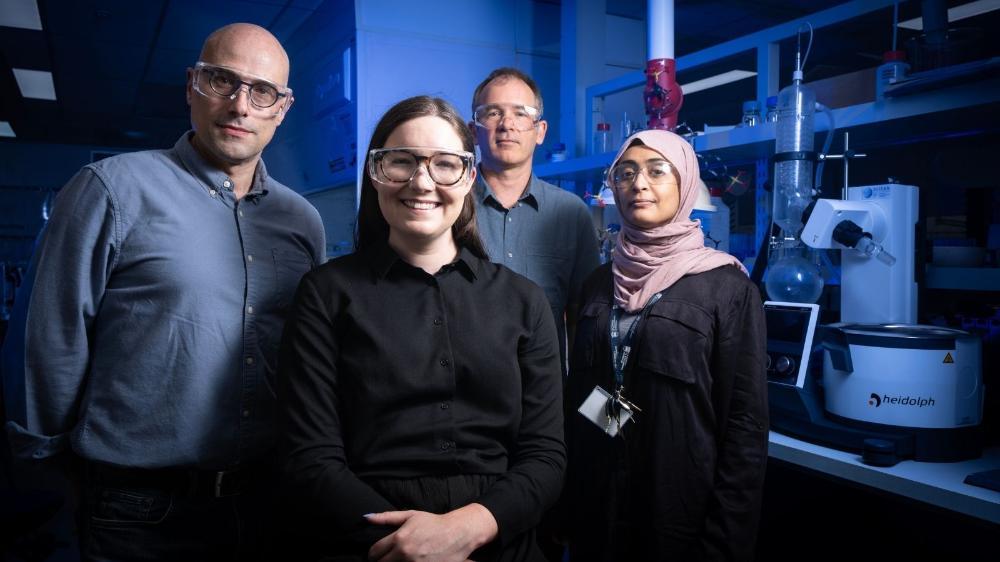

The team from Deakin’s (IFM), led by Dr Maryam Naebe, developed the bioplastic by repurposing cotton gin trash – the seeds, stems, short fibres and other waste by-products left behind from the ginning process used to separate cotton fibres.

“About 29 million tonnes of cotton lint is produced each year but up to a third of that ends up as cotton gin trash, where it’s then sent to landfill or burned, representing a major environmental impact and lost material value,” Dr Naebe said.

“Adding value to this waste product will give cotton growers and farmers an additional income stream, while also offering a sustainable alternative to harmful synthetic plastics.”

Dr Naebe said the results were part of a project from PhD candidate Abu Naser Md Ahsanul Haque, along with Associate Research Fellow Dr Rechana Remadevi. The team has been working on transforming cotton gin trash for more than 18 months.

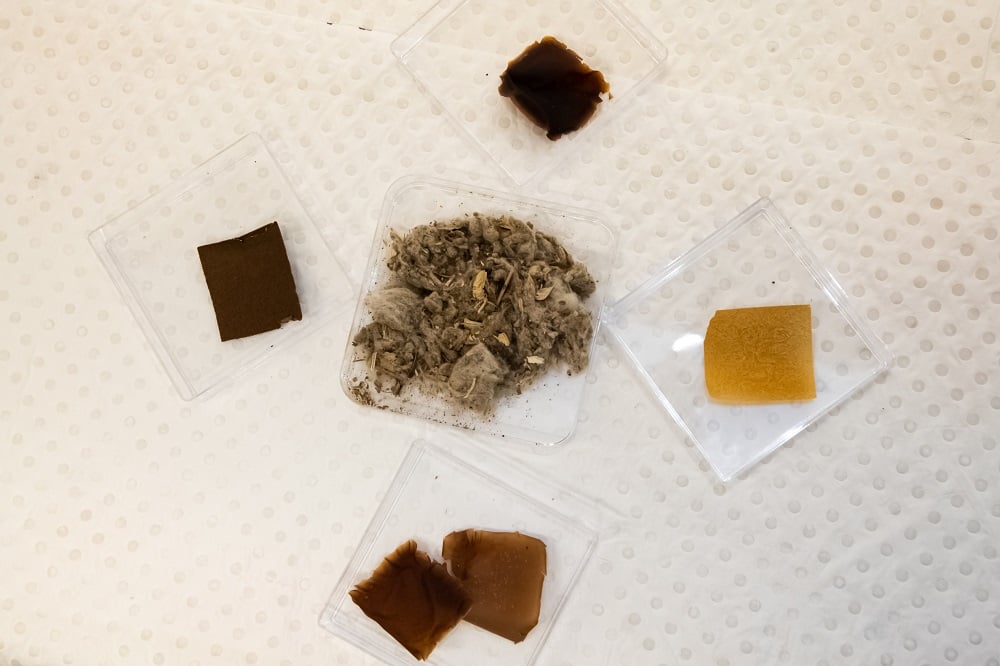

The researchers dissolve the cotton leftovers using environmentally-friendly chemicals and then re-cast the recovered bio polymer into a useable bioplastic film. The resulting material has a range of applications, such as a bale wrap, fertiliser and cotton seed packaging.

“Cotton gin trash is a promising source of renewable biomass, because when it’s broken down the resulting organic polymer can potentially be converted into a versatile biodegradable material,” Dr Naebe said.

“Compared to synthetic plastics, our bioplastic is made without the need for toxic chemicals – which makes it safer and cheaper to produce at a mass scale – and it has the added bonus of contributing to the circular economy.

“The bioplastic can biodegrade and turn into soil, which will then in turn be used to grow cotton, resulting in cotton gin trash during the ginning process, which can then be repurposed again into bioplastic.”

The team is now applying their process to other organic waste and fibrous plant materials such as lemongrass, hemp, almond shells, wheat straw, wood saw dust and wood shavings.

Recognised as one of Australia’s leading materials research institutes, Deakin’s IFM was established to address some of the major challenges facing society through innovations in materials design and performance.

“We want to lead and inspire innovations in materials science and engineering that have a transformational impact on society,” Dr Naebe said.

“Our mission at IFM is to keep pushing the boundaries of materials science in order to raise living standards across the globe – by redesigning materials for a circular economy, innovating with natural materials, and imparting them with extraordinary qualities.”