The digital twin is not a pipedream, but the next frontier of construction management, a UNSW expert says.

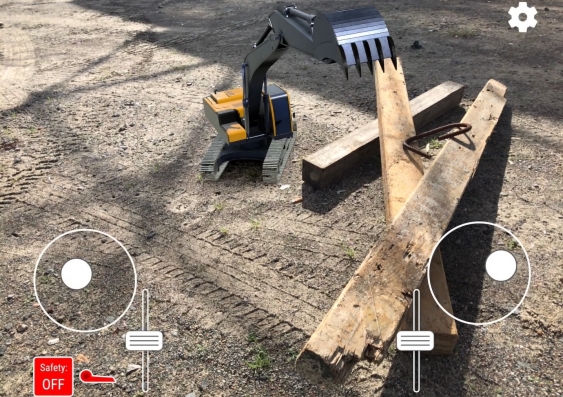

The augmented model of the excavator digital twin enabled for communicating with a physical Volvo EC360 excavator. Image: supplied.

You might be surprised to know that the modern construction site has a futuristic feel, implementing technologies like drones, laser scanners, virtual reality and the Internet of Things. But perhaps the most promising is the emerging ‘digital twin’, which, when adopted, will shake up the entire construction industry faster than even before, a UNSW construction management expert predicts.

“A digital twin is a digital replica of a physical entity utilising internet of things enabling two-way communications between them,” says Dr Samad Sepasgozar from UNSW Built Environment. “At the strategic level, the digital twin is a new game-changing approach to construction automation…that will transform the industry quicker than ever before.”

The idea is that for every physical item in the world, there could be a virtual replica with which it connects, housed in the cloud, collecting vital data on the physical item’s performance in real time, Dr Sepasgozar explains.

“Industry players might confuse this with Building Information Modelling. But unlike this previous technology, the digital twin also enables users to control equipment,” he says.

“So, it enables job-site tasks to be performed remotely, which is useful for working through disruptions like COVID-19.”

Dr Sepasgozar is currently developing a digital twin of an excavator, enabling improved diagnostics and analytics of the digging equipment’s performance.

“The digital twin and the physical excavator can communicate with each other, in real time. All the changes applied to one are applied to the other. For example, you can command the physical equipment and communicate with it [remotely]. On the other hand, the physical object will communicate with you so you can examine its performance, condition and productivity.” he says.

“So you can learn through data how to increase the productivity by changing the operation scenarios, like the attachments of the equipment, the distance between [equipment] and the specific floor of the building, you can analyse all [this] in real time.”

Improving safety in construction

One of the major safety challenges for construction management is operating the equipment safely, and controlling its downtime, Dr Sepasgozar says. From students who have no on-site experience to site managers well into their career, the digital twin can teach them how to evaluate hazards from the safety of afar and may remove the need to be present on-site altogether.

“So, for example, if the operator is not experienced enough, you can use the digital twin from your office, and then you can command and operate the excavator [remotely].

“It’s an online app on smartphones, so it’s much easier to use than you think … in terms of visualisation, in terms of controlling or using it – it is much easier than any previous digital automation technologies,” he says.

A digital twin could also be scalable to an entire construction site and facilitate simulation training exercises virtually to better prepare construction workers for the potentially life-threatening situations they may encounter, he says.

“It will cover all kinds of activities within a construction project – all of them, one day, will be connected to digital twins. We already have a lot of different types of sensors, drones, and other tools which will contribute to developing an entire construction digital twin,” he says.

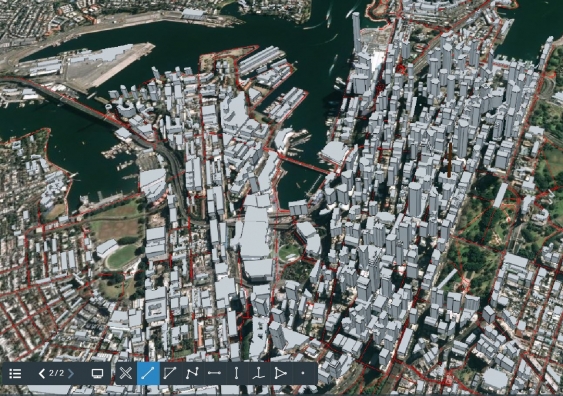

Dr Sepasgozar says that a digital twin is also a powerful tool for data visualisation and communication capable of illustrating the full picture of construction management with accurate, up-to-date datasets in a user-friendly format.

“Construction activities – whether it be a tunnelling project or light rail project – can have many impacts on neighbours, and [the] city from [an] emissions footprint [perspective], using the city resources, [affecting] safety and … disrupting the environment. This can be communicated accurately in real time with all citizens, construction companies and other stakeholders at the city level.”

Representation of building 3D models and the City of Sydney cycling network. Image: Supplied.

Digital twins will also help to make the construction industry more equitable and accessible for smaller players by giving them a platform, he says.

“Most previous technologies, like Building Information Modelling (BIM), is implemented by bigger guys in the industry. But [here] we are talking about smaller stakeholders, people on the ground level, family businesses, the subcontractors such as excavation contractors,” he says.

“Everyone can participate in the data generation, and of course, the sharing platform will be [richer], and that can be more useful to the construction companies and the community as a whole in terms of sharing data.”

Dr Sepasgozar says the appetite for digital twins in the built environment will carry over into other relevant businesses, adding that businesses that fail to jump on board will run the risk of being left behind. In fact, we are at a pivotal point, at a market and business level, he says, and the road to adoption will be a race.

“If you adopt this, the entire process of management and the automation process will be changed.”

There is no limit to the number of real-life assets that will have digital twin counterparts within the next few decades, as broader innovations in machine learning and connectivity advance, he says.

But ultimately, the success of the digital twin will depend on the construction users making the technology work for them.

“From the user perspective at the construction projects level, it’s not only about who is going to dominate the market. We need to think about the user benefit if we’re going to make the technology a success.”