(QCA) industrial design lecturer Dr Sam Canning has created a prototype ventilator from everyday items that could be used to save lives in developing countries.

Made from old bike parts and a bucket, the revolutionary prototype can be easily replicated in countries with limited resources.

Coronavirus ‘catastrophic’ for developing nations

Dr Canning said the lack of ventilators in developing countries meant that patients who presented at hospitals with respiratory symptoms from COVID-19 had little chance of surviving.

Dr Canning said the lack of ventilators in developing countries meant that patients who presented at hospitals with respiratory symptoms from COVID-19 had little chance of surviving.

Attempts by developing countries to buy medical equipment have been hampered by competition for supplies and price hikes by suppliers.

“South Sudan, a country of 11 million people, has just four ventilators. Ten countries in Africa have none. A coronavirus outbreak could be catastrophic in countries with struggling health systems,” said Dr Canning.

Necessity the mother of invention

“People in developing countries need simple designs that can easily be adapted on the ground – I hope my design can help save lives,” Dr Canning said.

The project was sparked by a conversation with a doctor who spent many years working in rural Papua New Guinea.

“He told me that he and a team of medical students had kept a patient alive for five days by manually squeezing a ventilator bag, and I was immediately interested in the bare minimum of technology you would need to keep someone alive,” Dr Canning said.

“The aim of this project is to create something useful for people without access to sophisticated medical equipment and no hope of getting any.”

‘Design has a key role to play in this crisis’

Dr Canning’s prototype is an example of the human-centred ethos at the heart of the QCA’s design program.

“Design is about helping people, and it has a key role to play in this crisis,” he said.

“It’s about finding ways to make people’s lives better.”

Students step up as part of design challenge

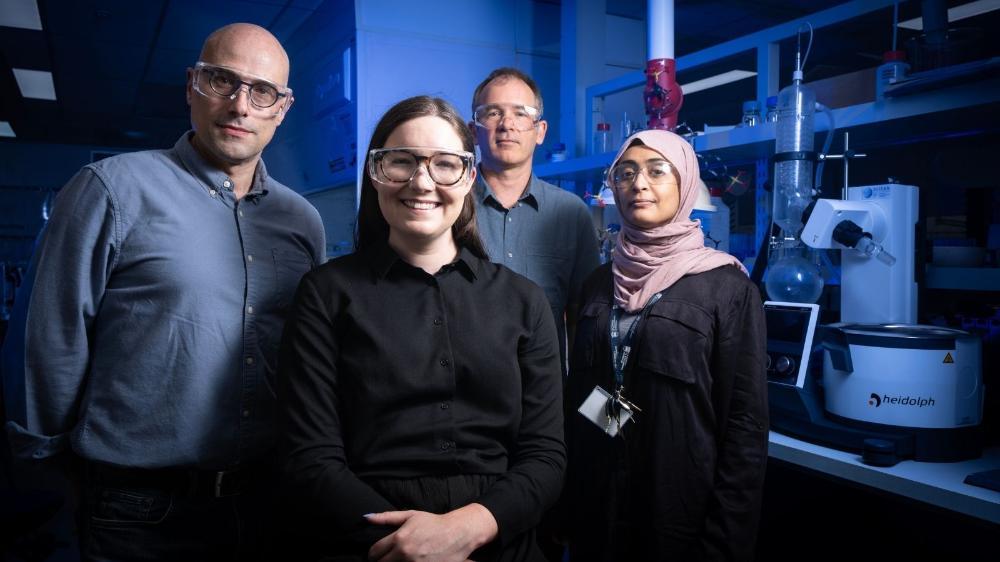

The senior design lecturer is also overseeing a student design challenge, with dozens of QCA students working with industry mentors to create prototypes of masks, gowns and face shields for frontline healthcare professionals.

Griffith’s Advanced Design and Prototyping Technologies Institute (ADaPT) and Queensland College of Art (QCA) design studio were among the teams that helped manufacture essential protective equipment for frontline health workers in Australia last month.

As part of a call-out by the state’s health authorities, face shields and other personal protective equipment (PPE) were created using 3D printers from a number of facilities and schools across the university to help maintain domestic supplies during the COVID-19 crisis.