Researchers from the Max Planck Society, RWTH Aachen University, and Covestro AG nominated for CO2-based plastics

They have developed a new raw material for the chemical industry. Thanks to the work of Walter Leitner, Christoph Gürtler, and Berit Stange, the greenhouse gas CO2, of all things, can now be used to replace part of the petroleum from which components for foam and adhesives, among other things, are made. The catalytic process and the first products produced with it have earned the three chemists a place among the last three competing teams for the 2019 German Future Prize. Walter Leitner is Director at the Max Planck Institute for Chemical Energy Conversion and Professor at RWTH Aachen University, Christoph Gürtler is Head of New Processes and Products at Covestro, and Berit Stange is Head of the Polyurethane Recycling Economy Division. The finalists present their innovation today at the Deutsches Museum in Munich. The decision as to who will win the prize awarded by the Federal President will be made at the end of November.

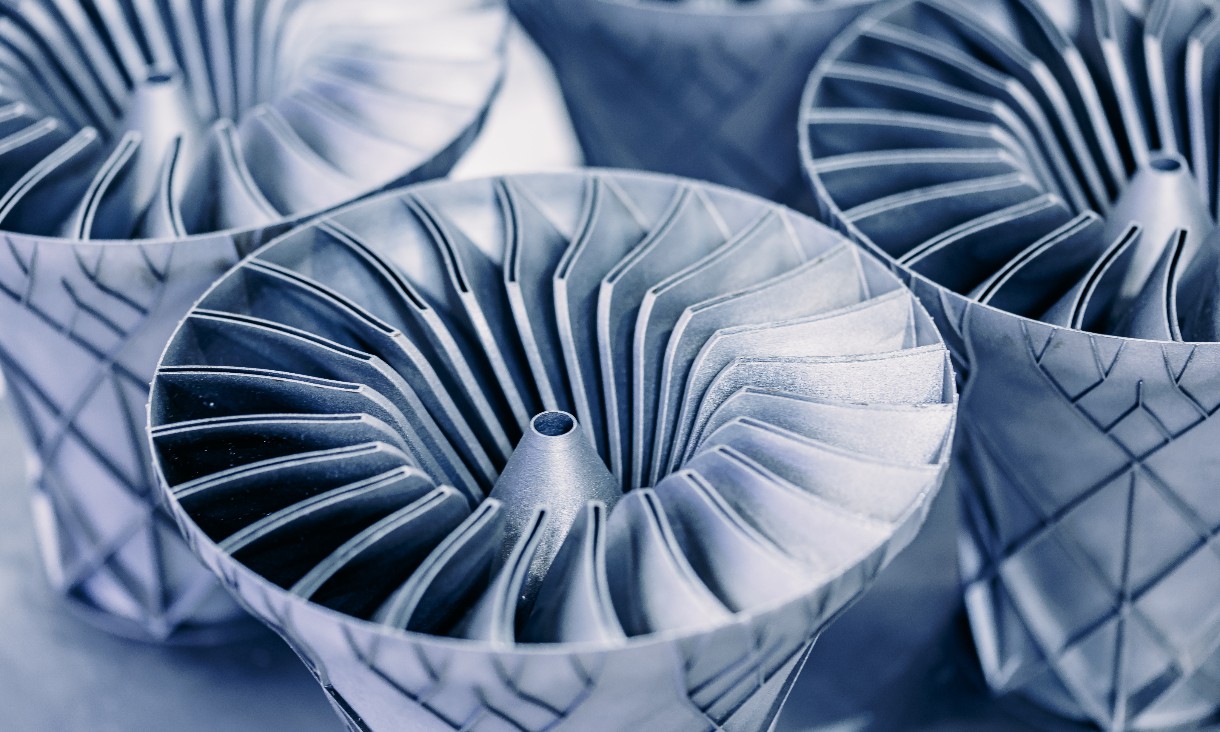

There are quite different views on CO2: Most people see it primarily as a gas that leads to climate warming. But for Walter Leitner, Christoph Gürtler, and Berit Stange, CO2 is also a source of carbon as well as an essential component of most plastic, fuels, and chemical industrial products in general. The researchers are using the greenhouse gas to replace part of the petroleum used for chemical production. They have developed a process with which Covestro AG can produce up to 5000 tonnes of polyol per year in a pilot plant. Other companies can further process this substance into polyurethanes, which are already used as foams in mattresses or as adhesives in sports flooring. However, there are countless other applications for polyurethanes (e.g. soft foams in car seats or rigid foams in insulating materials). Nearly four million tonnes of polyols are needed annually for flexible foams alone.

The right catalyst gets CO2 going

The jury of the German Future Prize was so impressed by the innovation of the three chemists that it selected them as one of the last three teams for the final round. The winning team will be selected by Federal President Frank-Walter Steinmeier on 27 November at an awards ceremony in Berlin, which will be broadcast by ZDF. “Just being nominated for the German Future Prize confirms our approach of developing sustainable technologies and products through close collaboration between academic and industrial researchers – even if we are initially faced with a few obstacles”, says Walter Leitner.

The researchers did indeed have to overcome some obstacles on the way to plastics, some of which are made from CO2. This started with the properties of CO2: The gas is highly inert; it is therefore no coincidence that it is used in fire extinguishers. For this reason a great deal of energy is required to get it to react with other substances. The right catalyst helps. A catalyst lowers the activation energy for the conversion and steers it in a desired direction. The researchers at the Catalytic Center CAT, a joint facility of RWTH Aachen University and Covestro AG, and at Covestro, have found a suitable catalyst for incorporating CO2 into the polyol. And because they can explain how it works, they were also able to optimize the production process for the polyols. Among other things, they wanted to be able to precisely control how much CO2 is incorporated into the polyol. “We have created the preconditions for a chemical process with which we can produce the new CO2 polyols on an industrial scale”, says Christoph Gürtler.

A model for defossilising other chemical processes

Walter Leitner, Christoph Gürtler, and Berit Stange made the process more sustainable by working out many elaborate details. Covestro experts as well as external experts proved this by analysing the ecological balance. The controlled incorporation of CO2 can even improve the properties of the product. Thus, the innovation not only makes sense from an ecological perspective but also an economical one”, says Berit Stange.

The CO2-based production process for polyols also opens up prospects beyond the manufacture of these substances and the polyurethanes produced from them. “We have shown that it is possible to use CO2 as a raw material and thus reduce the CO2 footprint of the chemical industry”, says Walter Leitner. “In this way, we hope to defossilize further chemical processes using this model. Or in other words, make them more independent of fossil-based raw materials. This goal motivates us to continue doing basic research in the field of catalytic CO2 conversion.”

PH