Rick Luhrs

Rick Luhrs

Buying an adjoining farm has given sheep producer Rick Luhrs and members of his local MLA-funded Healthy Soils Group the perfect opportunity to compare how different grazing and fertiliser histories influence soil characteristics and soil carbon.

Rick and Marni Luhrs operate a Merino enterprise across their two properties near Mooralla, Victoria, running 5,000 Merino ewes joined to Merino and Terminal sires in equal halves.

The flock includes 400–500 stud Poll Merino ewes which form the Mooralla Poll stud that supplies the Luhrs with rams and produces sale rams as well.

“Our flock is 19 micron, non-mulesed, dual purpose Merino which we shear three times in two years,” Rick said.

The two properties are based on typical Dundas Tablelands sandy clay loams and clay loam soil types and both receive an average rainfall of 550mm a year, although the variation can range from 320–800mm.

Two properties, two approaches

On their home property, ‘Yama’, the Luhrs have used rotational grazing for the past eight years and the property has a long history of applications of reactive rock phosphate, chicken manure, lime and gypsum.

“Dad has used a lot of natural fertilisers such as reactive rock phosphate and chicken manure and we have kept that program going on the farm,” Rick said.

“Dad used to set stock, but nine years ago we began rotational grazing and containment feeding to protect pastures.

“We’ve seen benefits with the change to rotational grazing which has resulted in improved pasture utilisation and reduced the build-up of nutrient in stock camps.

“Rotational grazing has been increasing our soil carbon levels and, with it, increasing our water infiltration.”

Meanwhile, on their adjoining, 80ha block purchased in 2019, the property has been subject to conventional fertiliser use and set stocking rates for the past 15 years.

This difference in management across the two properties was what caught the attention of local Hamilton Healthy Soils Group.

Composed of members from Southern Farming Systems, Cavendish Best Wool Best Lamb Group and the Grassland Society of Southern Australia Pasture Tech Group, the Hamilton Healthy Soils group was keen to investigate the differences in soil carbon on the two blocks.

Particularly, group coordinator Michelle McClure said, the group was interested in seeing how the different management strategies applied across the two blocks could be linked to an impact on soil carbon levels.

Comparing the carbon

To investigate the differences in soil carbon levels and what management strategies could be influencing these changes across the two properties, the group engaged Precision Agriculture to test and map 10ha of a similar class of the two paddocks (Figure 1).

Figure 1: Satellite map of the two 10ha areas across the Luhrs’ properties.

Both 10ha blocks were sampled on a 1ha grid with a standard sampling depth of 0–10cm, with the result presented in a series of colour coded maps for variation across both paddocks for a range of soil tests including pH (CaCl2), Colwell P, potassium and Cation Exchange Capacity, with three deep soil cores taken in each block.

The results showed that on Rick’s home block, 42% of the 10ha tested had a soil organic carbon (SOC) range between 3.0–3.3% and the other 58% ranged between 1.9–2.9%.

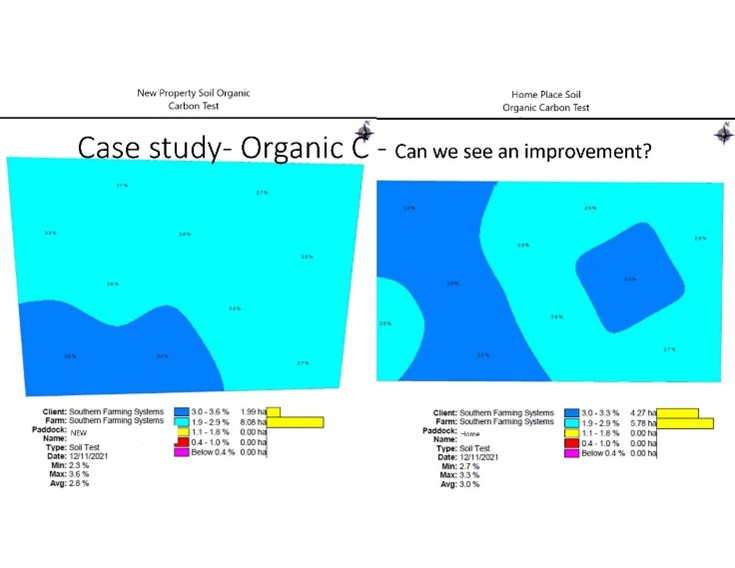

Meanwhile, on the new block, only 20% of the 10ha ranged between 3.0–3.6% and 80% in the 1.9–2.9% range of soil organic carbon (Figure 2).

Figure 2: The Soil Organic Carbon (SOC) results of both paddocks.

“The new block only had the higher SOC figures in the small stock camp area,” Michelle said.

“The maps showed the group how variable SOC can be across 10ha, let alone a full-sized paddock – and that Rick’s management of the home place may have influenced the soil organic carbon.”

Calculations for boosting carbon storage

During group discussions, Southern Farming Systems’ Research and Extension Officer Lisa Miller, took the group through what herbage mass is required to increase soil organic carbon by 1%.

Many members of the group were surprised by the amount of extra dry matter needed and the amount of time it would take to produce this.

“To get a 1% change in soil organic carbon in the top 0–10cm with a soil of bulk density 1.3 g/cm3, the required change is 13 tonnes of carbon per hectare,” Lisa said.

“Organic matter (OM) contains 58% organic carbon, so an increase of 13 tonnes of carbon per hectare is equivalent to adding 22 tonnes/ha of OM.

“Unfortunately, however, microbes eat 90% of it and only 10% remains to contribute to the soil carbon pool, so we need to grow an extra 224t OM/ha of both roots and shoots.

“In pasture, the ratio is about 40% shoots and 60% roots, so you would have to grow 90 tonnes of shoot OM and 134 tonnes of root organic matter per hectare.

“If typical pasture production is 10 tonnes of DM/ha each year and we increase pasture growth by 4t DM/ha each year, it means it would take 22 years to change organic carbon by 1% – so it isn’t going to happen overnight, it’s a commitment for the long term.

“However, the good news is that increasing pasture growth by having good soil fertility, reducing soil acidity, rotational grazing and keeping good groundcover to avoid soil loss will increase productivity and supply of organic matter, thereby building organic carbon.”

Removing soil limits

From looking at the test results of the Luhrs’ properties, Michelle suggested the Luhrs will need to target other soil limiting factors such as soil pH and phosphorus to allow more pasture growth and boost their soil organic carbon percentage.

In 2022, Rick plans to apply lime on both paddocks to address the soil acidity on both paddocks through his whole farm liming plan. In the meantime, however, he remains impressed with how his current grazing management has served to boost soil carbon.

“The test results really highlighted that rotational grazing is working in terms of improving soil carbon, and the benefits that go with it,” Rick said.