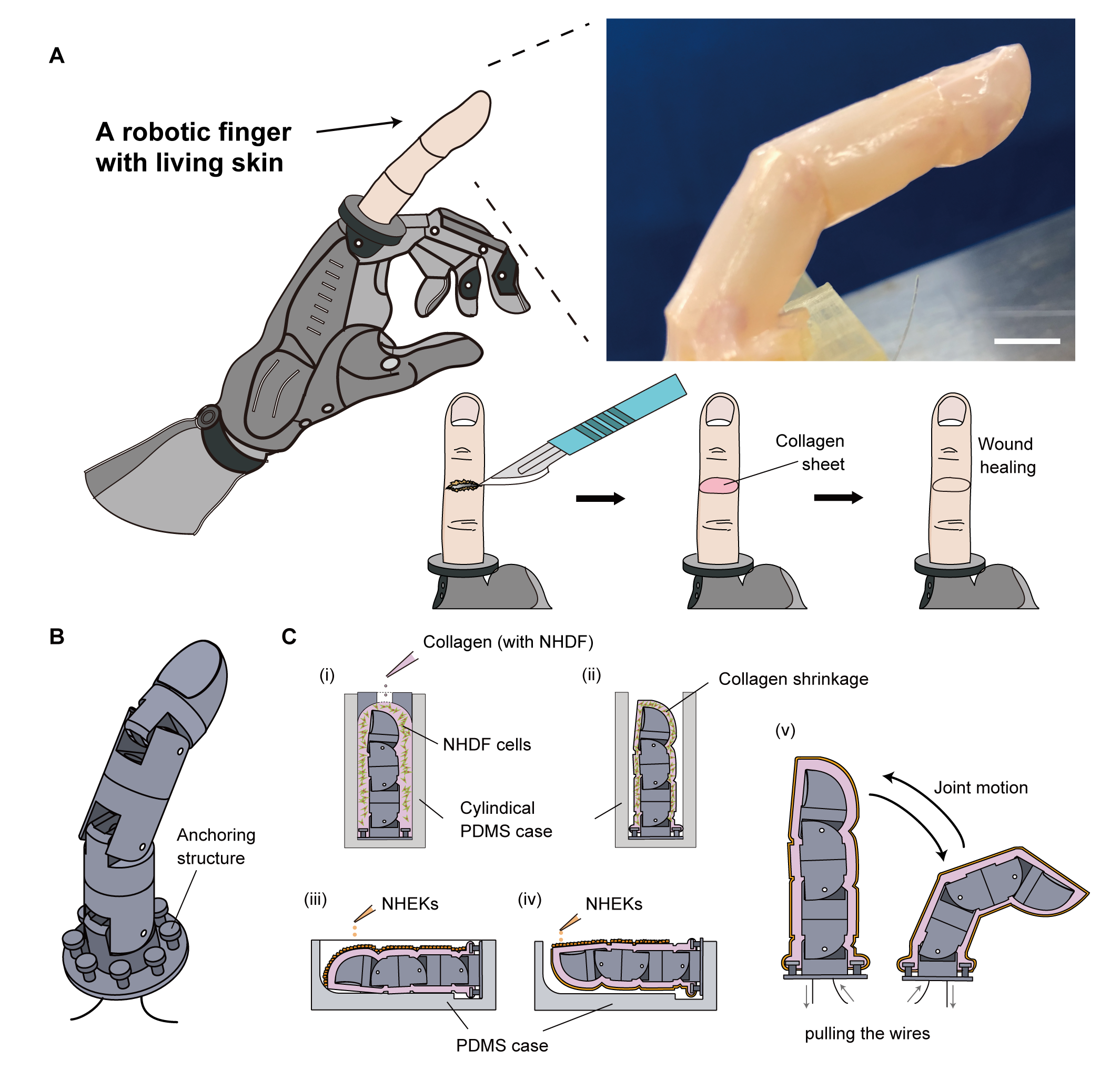

Robotic finger. Illustration showing the cutting and healing process of the robotic finger (A), its anchoring structure (B) and fabrication process (C). ©2022 Takeuchi et al.

Researchers from the University of Tokyo pool knowledge of robotics and tissue culturing to create a controllable robotic finger covered with living skin tissue. The robotic digit has living cells and supporting organic material grown on top of it for ideal shaping and strength. As the skin is soft and can even heal itself, the finger could be useful in applications that require a gentle touch but also robustness. The team aims to add other kinds of cells into future iterations, giving devices the ability to sense as we do.

Professor Shoji Takeuchi is a pioneer in the field of biohybrid robots, the intersection of robotics and bioengineering. Together with researchers from around the University of Tokyo, he explores things such as artificial muscles, synthetic odor receptors, lab-grown meat, and more. His most recent creation is both inspired by and aims to aid medical research on skin damage such as deep wounds and burns, as well as help advance manufacturing.

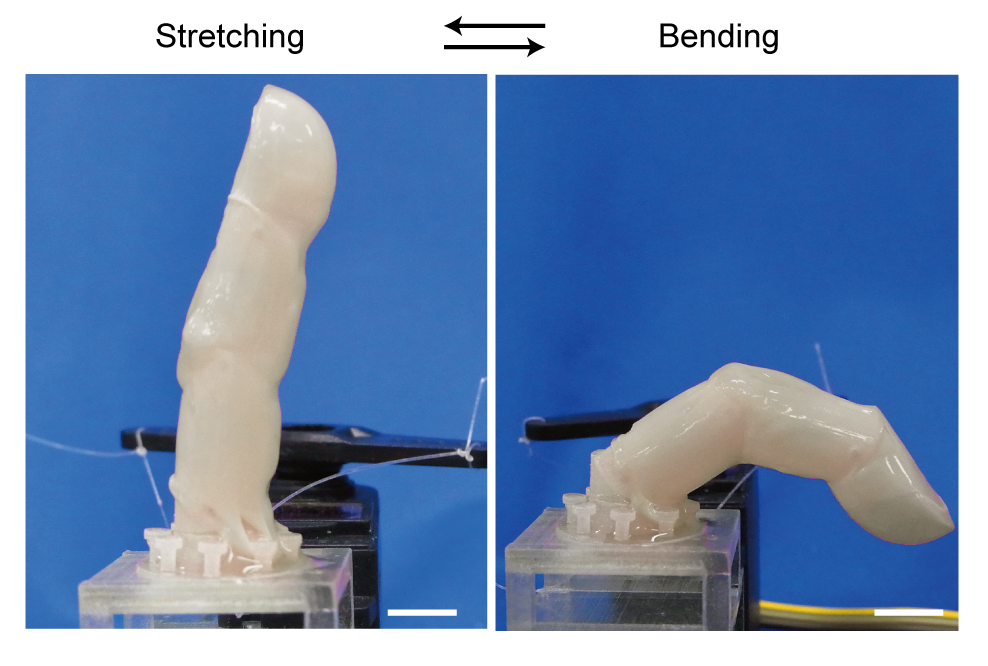

“We have created a working robotic finger that articulates just as ours does, and is covered by a kind of artificial skin that can heal itself,” said Takeuchi. “Our skin model is a complex three-dimensional matrix that is grown in situ on the finger itself. It is not grown separately then cut to size and adhered to the device; our method provides a more complete covering and is more strongly anchored too.”

Robotic finger bending. The main advantage of growing skin on the finger directly is that it’s always going to be a perfect fit, allowing the device to bend easily. If the skin was cut from a flat sheet and adhered to the finger, the imperfect shapes and seams would interfere with the movement. ©2022 Takeuchi et al.

Three-dimensional skin models have been used for some time for cosmetic and drug research and testing, but this is the first time such materials have been used on a working robot. In this case, the synthetic skin is made from a lightweight collagen matrix known as a hydrogel, within which several kinds of living skin cells called fibroblasts and keratinocytes are grown. The skin is grown directly on the robotic component which proved to be one of the more challenging aspects of this research, requiring specially engineered structures that can anchor the collagen matrix to them, but it was worth it for the aforementioned benefits.

“Our creation is not only soft like real skin but can repair itself if cut or damaged in some way. So we imagine it could be useful in industries where in situ repairability is important as are humanlike qualities, such as dexterity and a light touch,” said Takeuchi. “In the future, we will develop more advanced versions by reproducing some of the organs found in skin, such as sensory cells, hair follicles and sweat glands. Also, we would like to try to coat larger structures.”

The main long-term aim for this research is to open up new possibilities in advanced manufacturing industries. Having humanlike manipulators could allow for the automation of things currently only achievable by highly skilled professionals. Other areas such as cosmetics, pharmaceuticals and regenerative medicine could also benefit. This could potentially reduce cost, time and complexity of research in these areas and could even reduce the need for animal testing.

Robotic finger healing. Photographs showing the stages of repair after the test finger was cut and patched with a small section of collagen. This takes place in a liquid medium. ©2022 Takeuchi et al.