A sharkskin-inspired coating on planes will save thousands of dollars per flight and slash carbon emissions, says Aussie start-up, MicroTau.

The Clean Energy Finance Corporation (CEFC) today announces a $5.6 million investment in MicroTau’s ‘sharkskin’ technology developed with the help of the Australian ³Ô¹ÏÍøÕ¾ Fabrication Facility (ANFF).

Sharks famously swim smoothly and quietly, helped by their unique skin with thousands of overlapping layers of tiny ‘scales’ or denticles to reduce their drag in the water.

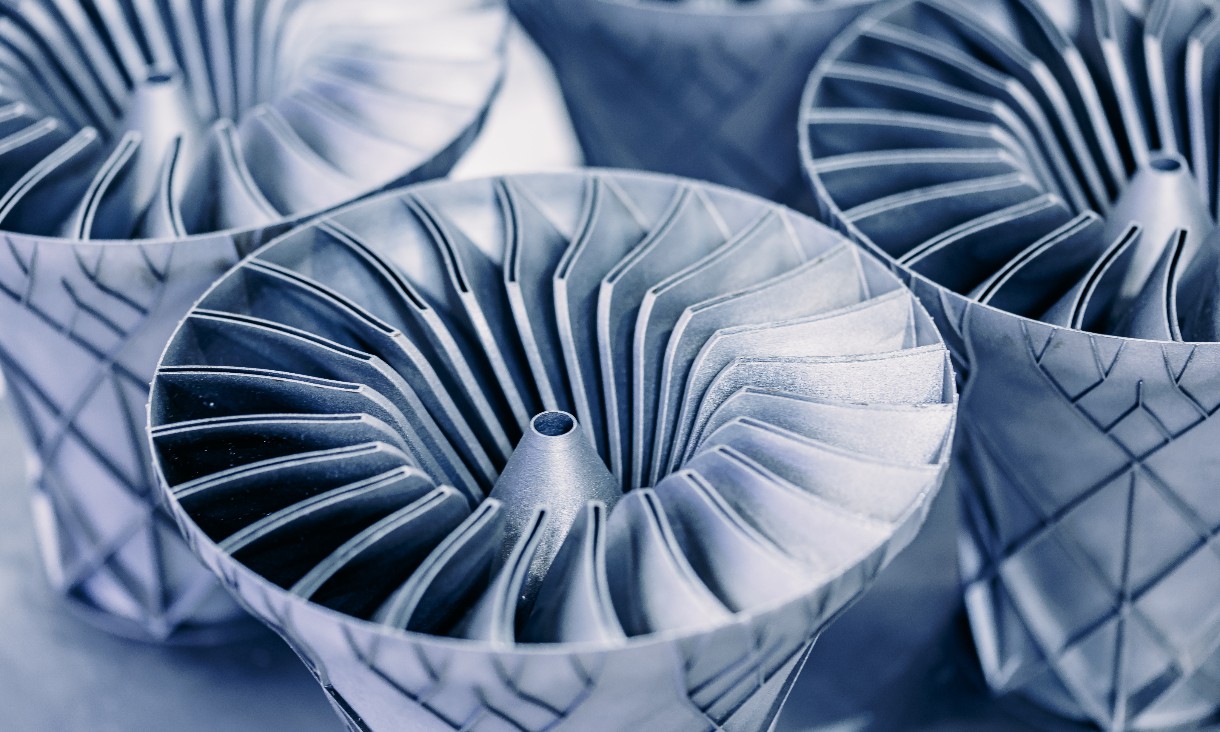

Mimicking this structure on airplanes reduces turbulence, increases flying speed, and cuts fuel emissions and cost. Unfortunately, it is excruciatingly difficult to replicate the microscopic grooves and bumps with traditional manufacturing.

MicroTau have solved this puzzle using specialist laser manufacturing technology to rapidly produce the shark skin pattern in a light-curable material onto large, self-adhesive patches. Today’s funding announcement will allow them to scale-up manufacturing and grow their team of scientists, engineers, and business development specialists.

MicoTau founder Henry Bilinsky says the expanded team will pursue certification to produce parts for wide-body aircraft, bringing his film a step closer to market.

“Were we to apply our film to an Airbus A380 today, a single flight from Sydney to LA would save AUD$8,554 in fuel and 18,018kg of CO2emissions. Thousands of dollars per flight adds up to millions over the life of the aircraft.

“That’s just using current technology to retrofit an existing plane. We could see efficiency improvements as high as 10% as we refine the design.”

Henry’s idea for ‘Direct Contactless Manufacturing,’ which creates microscopic ridges called ‘riblets’, was the winning entry in a 2015 US Airforce open innovation competition. But making his idea a reality would be a hugely challenging process.

“The grooves between riblets for aircraft are about 50 microns wide, or half as wide as human hair. On the other hand, we need hundreds of square metres of riblets to cover a plane wing, so we have to work at the micro and macro scale at the same time,” Henry explains.

To solve this problem, MicroTau turned to ANFF-NSW’s Research & Prototype Foundry based at the University of Sydney.

The Foundry has million dollars of highly specialised manufacturing equipment available to researchers and industry, funded by the Australian government through NCRIS, the ³Ô¹ÏÍøÕ¾ Collaborative Research Infrastructure Strategy, State Government and the University of Sydney’s Core Research Facilities program.

“Fast turnarounds and local production mean we can rapidly test and customise new optical components. We were able to quickly produce new designs at a low cost, something that would have otherwise taken months and thousands of dollars to do,” says Henry.

Nadia Court, the technical director of the Research and Prototype Foundry, says MicroTau is the kind of success story they were created to help.

“We have a public library approach, so anyone with a safety certificate can book to use this machinery. We charge companies a fee per hour, but start-ups like MicroTau can use NSW government tech vouchers to cover their time.”

“MicroTau’s optical components are made with a Heidelberg Laser. The same laser is used by physicists studying the movement of individual light particles and bio-medical researchers simulating the movement of blood through tiny capillaries.”

“In the Foundry you have people doing fundamental research, next to material scientists working for major companies, next to PhD students. All these different approaches collide and spark new ideas. MicroTau is a wonderful example of the creative, clever community we want to see in Australia.”