Installing a new component in a nuclear reactor could be compared to working in outer space

repairing or replacing a part on the International Space Station.

The environment is unique, working conditions are difficult and awkward and all the extensive preparation cannot prepare you for all the unexpected. Like protocols in space, safety guides every action in the reactor environment.

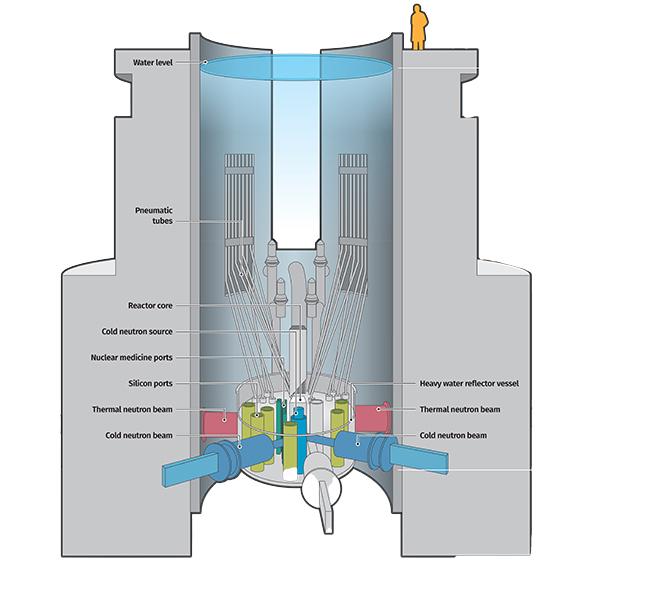

The installation of a Cold Neutron Source (CNS), a component that reduces the energy and speed of the neutrons from a research reactor for use in scientific instruments, was successfully completed in September 2024.

The OPAL Reactor Manager said that since OPAL began operations, the successful installation of the CNS is the most significant achievement the group has made as team. It is a technical milestone with scientific, economic, and national significance. It confirms that OPAL is one of the best and most advanced reactors in the world and will continue to bring benefits in the peaceful uses of nuclear science and technology to Australia.

The new and improved cold neutron source offers ANSTO greater levels of scientific capability. Cold neutrons allow scientists to investigate the unique properties of larger molecules such as proteins and polymers.

Replacement of the cold neutron source is a major milestone for ANSTO, demonstrating our expertise in engineering design and major maintenance activities.

Chronology

Replacement of the cold neutron source is a major milestone for ANSTO, demonstrating our expertise in engineering design and major maintenance activities.

Planning and design activities commenced in 2015, working towards the 2024 shutdown timeline. The Cold Neutron Source was replaced over a planned six-month shutdown, from March to September 2024.

Andrew Eltobaji has been the project manager of the CNS upgrade since its conception, working closely with 20 core team members but drawing on the expertise of 30 to 40 more contributors from diverse disciplines across ANSTO.

The specialist Engineering, Maintenance and Operations team was made up of nuclear engineers, reactor managers and supervisors, technicians, welders, and radiation safety experts.

In the planning stages, the team reached out to several other international research reactors to identify what other facilities had undertaken similar major shutdown activities. This investigation quickly identified that the planned Cold Neutron Source replacement was a unique activity not undertaken by other research reactor facilities. This resulted in the majority of design development work and maintenance activities being undertaken by ANSTO engineering and maintenance experts.

To prepare technicians for the operation, a full-scale mock-up of the CNS and reactor environment was constructed to assist in the planning and training of supervisors and technicians. This allowed team members to undertake comprehensive training in conditions which mimicked the real environment.

The mock up enabled the team to develop the process for replacing the CNS and develop the specialist tooling required.

The training mock up facility was used to rehearse the CNS installation activities in a simulated environment and allowed them to complete tasks safely. A team of supervisors were trained using the mock-up to prepare them for their training of technicians.

The training mock-up facility was used to rehearse the CNS installation activities in a simulated environment and allowed them to complete the task safely. A team of supervisors were trained using the mock-up to prepare them for their training of technicians.

During the engineering design process, every component in the installation was modelled in a 3D computer simulation. This was used to fabricate prototype components to initially build the full-scale mock-up then used to optimise the design of the CNS itself.

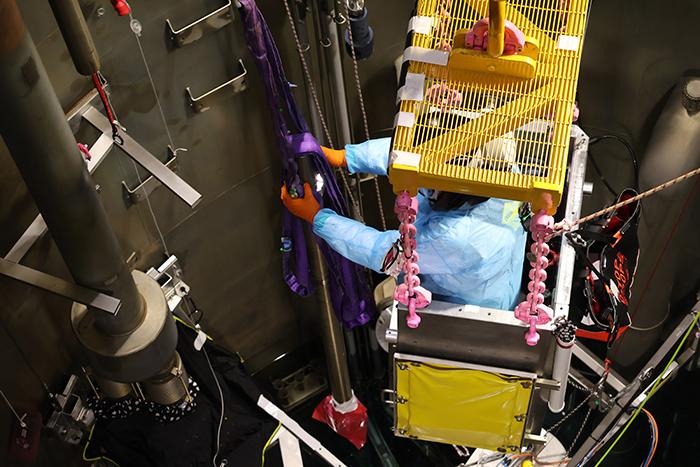

Prior to the commencement of the installation sequence, the level of water in the reactor pool was reduced and a number of reactor components, including pipework, had to be removed to allow access to the old CNS.

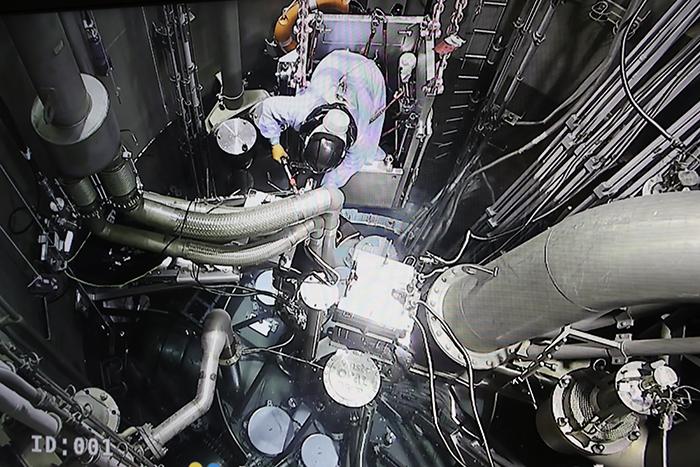

The CNS together with associated pipework were lifted out of the reactor and placed in a special shielded device with precision. This was done remotely using cameras and no direct interaction with technicians.

The replacement CNS structure was eight metres tall and had to be installed precisely vertical. Again, this was conducted remotely using cameras and required positioning accuracy to within a few millimetres. Once in place, the various pipes suppling either helium, deuterium or vacuum services were connected and tested.

The CNS Cryogenic refrigeration system cools helium down to -253°C which in turn liquifies deuterium, which has a cooling effect on the neutrons.

Many measures were in place to ensure the safety of maintenance technicians.

Firstly – technicians wore lightweight long sleeve t-shirts and long pants. This was covered by a breathable Tyvek suit which included a filtered ventilation air hood respirator and finally double layered gloves and safety boots.

Radio communication with technicians was maintained and a wireless health monitoring system was used to monitor body temperature, heart rate and radiological exposure.

“Of all the tasks, the most technically challenging aspect of the entire operation was the re-assembly of process pipework to the new CNS, ” said Andrew.

“All pipework flanges are sealed with metallic seals. These seals require precision assembly to avoid any damage.” he said.

The need for precision and safety considerations makes it necessary to do everything very carefully. This is where the training and rehearsals in the mock-up helped tremendously.

The design of the replacement CNS is slightly different to the old CNS, and it is expected that the replacement CNS will provide a slight performance improvement. The undertook an experiment using to measure the neutron flux and wavelength spectrum of the neutrons and determine if the CNS is delivering neutrons at the expected performance gains.

“Using Bilby, we can count if the number of neutrons coming from the replacement CNS has been increased, which was one of drivers for its replacement,” said Dr Jamie Schulz.

The reactor operations room monitors sensors in the CNS plant, along with all other reactor components.

With the re-start of the reactor and the flow of cold and thermal neutrons restored, scientists can once again use their powerful ability to reveal information about materials.

The CNS provides more cold or slow neutrons, as they are described. Cold neutrons are not physically cold but have a lower energy, less than 5 meV, than the thermal neutrons in the reactor reflector vessel that have been created by nuclear fission. Beams of neutrons are used to study the structure and dynamics of materials, with both the cold and thermal neutrons used in different experiments.

The replacement CNS is about three metres in height, has a complex shape and weighs about 200 kilograms when empty.