Michael Hughes focuses on maximising efficiency and meeting market specifications in his NSW Angus feedlot, so he was keen to try a new handheld device which could take the operation’s carcase performance to the next level.

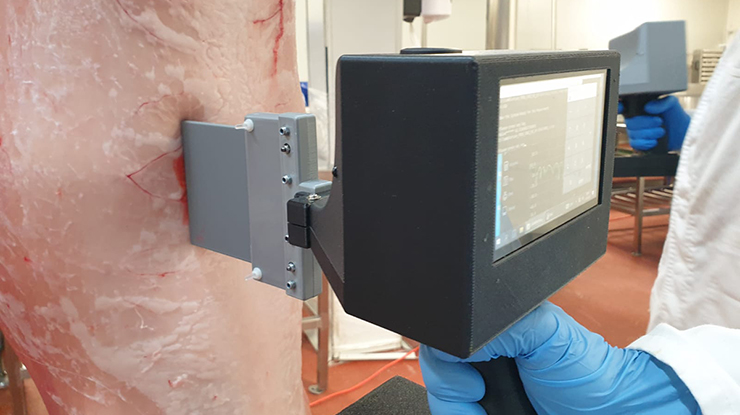

The system, which uses microwave signals to measure carcase composition, is being trialled on Michael’s feeder cows in an effort to boost feed efficiency and carcase performance. It’s an outcome of Murdoch University’s Advanced Livestock Measurement Technologies program (ALMTech), supported by Meat and Livestock Australia (MLA), see story opposite.

“At the moment, we’re mainly using it to measure fat on the P8 (rump) of our feeder cows,” Michael said.

“Our feedlot is unique in that we’re putting older cows on feed for 60 days before turning them off, so we get cows coming into the feedlot in various conditions, from store condition to quite fat.

“We want to use the system to work out what body fat the animal is carrying at the time of entry, so we can tailor their feed ration.

“The system itself is very quick and simple – we just touch the device on the animal’s body when they come into the crush and pull the trigger to take the fat measurement.”

Knowledge is power

Having this measure of carcase composition ahead of time could prove key to Michael’s efforts – streamlining costs and helping meet market specifications.

“At the moment, our kill sheets indicate our cows have anywhere between 10–12mm to 45–50mm of P8 fat when processed, with 10–15mm the ideal measurement,” Michael said.

“By using the system to measure fat on each individual animal, we can now adjust our management to keep within the 10–15mm ideal range.

“For example, we might elect not to feed animals that are already too fat and instead choose another option for them other than the feedlot, such as doing a grassfed kill.

“Similarly, it can help avoid overfeeding, as you can tailor rations to reduce the cost of investment in the animal.”

Once the device is accredited for commercial use, Michael hopes processors will also reap the benefits of the technology.

“If we’re not sending animals over that ideal 10–15mm fat measurement, processors will minimise the waste they create in the boning room through trimming,” Michael said.

“Not only will this mean it take less time to process the carcase, but they will also get more premium product.”

Food for thought

While the technology is still in the prototype stage, Michael is confident its functionality will continue to expand to make it well worth the investment.

“Once commercially available, we expect the system to provide an instantaneous, accurate reading of P8 fat. Into the future, we could even look at how it can help assess eating quality based on intramuscular fat,” Michael said.

“The possibilities are exciting – and applications could exist not just for cattle, but for sheep as well.”

Latest news