Toyota Motor Corporation (Toyota) recently held an informational session, Toyota Monozukuri Workshop, under the theme of Changing the Future of Carmaking. Executive Officer and Chief Production Officer Kazuaki Shingo explained the inheritance and evolution of the Toyota way of monozukuri (manufacturing) by changing plant environments, and changing the future of automobiles through human-centered manufacturing. Various monozukuri technologies being developed at the Teiho, Myochi, and Motomachi plants were also on display.

Table of contents

In this workshop, we will introduce an approach to manufacturing that embodies the technologies unveiled at the Toyota Technical Workshop held in June. The theme of this workshop is Changing the Plant Environment and the Future of Cars through Human-centered Monozukuri.

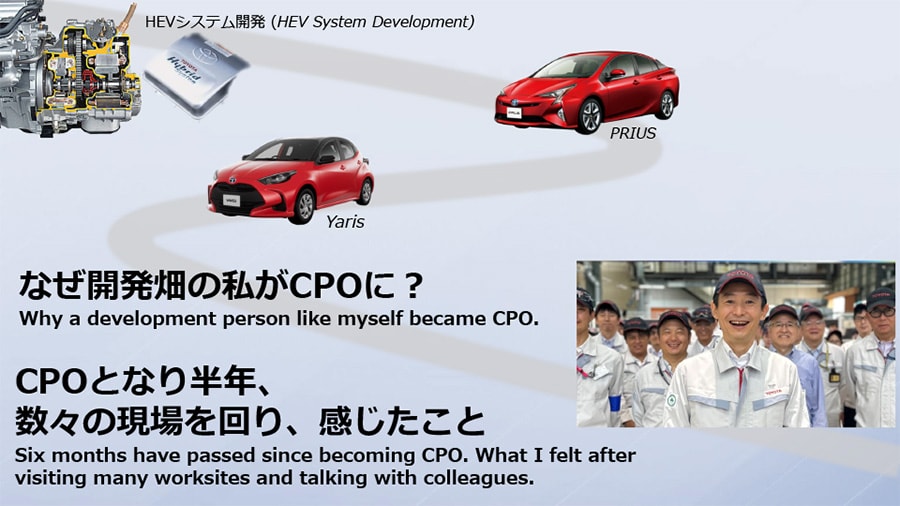

I have been in charge of development for many years, and helped develop the hybrid system for the first-generation Prius and on planning vehicles such as the Corolla, Prius, and Yaris. I was honestly surprised when I was offered the position of CPO, but I believe it was because of the great expectation that in an age when there is no right answer, development and production should transcend barriers and work together like a venture company to create the future. Also, Chairman Toyoda told me that he wanted our plants to be places where workers could be more energetic and active. I would like to share with you three things I felt during my six-month visit to the sites.

First, wherever I go at Toyota, I sense that the same spirit of wanting to make someone’s work easier and making everyone smile, a spirit that has been present since the company’s founding is still alive and well at the genba. Just as when Sakichi Toyoda invented the automatic loom, that startup power is still alive and well today: creating something out of nothing, making improvements, and introducing attractive products to the world.

The second is that monozukuri that is highly skilled and technologically advances is being truly passed down. In automation, even as human operators teach robots how to achieve both high quality and high productivity, human operators are raising the level of their own skills and in turn teaching these improved skills to the robots. This cycle is continuing and the skills and technologies refined ever more.

The third is training human resources and strength of the workplace. We realized that the power of the genba is to have TPS take root, to have everyone feel a passion for manufacturing and pursue kaizen themselves, and to train people for just those things. This genba power has enabled us to achieve a full lineup of 10 million units, answering the diverse needs of our customers.

The automotive industry is now entering an era of transformation, a change in the game where survival is at stake. It is precisely because we are in such an era that it is increasingly important to firmly pass on Toyota’s techniques, and the three things I felt on the genba, the monozukuri strengths that only Toyota possesses.

From here, I would like to talk about my thoughts as CPO on the evolution of monozukuri. I want to change the future of carmaking through Toyota’s skill. To achieve this, we need to evolve monozukuri through the fusion of skills/technology and digital & innovative technologies, and to shorten lead times, to be agile and continually take on challenges. Toyota has a TPS-based technique called lead-time reduction. I believe that the strength of Toyota’s manufacturing lies in increasing the speed of evolution and responding to the changes of the times.

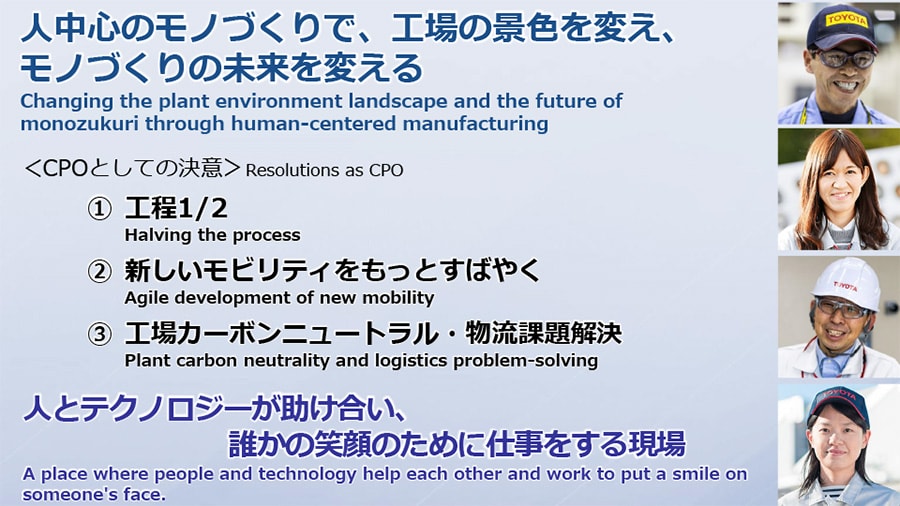

We will also change the future of monozukuri by changing the plant environment landscape. To do that, I am willing to break the production department status quo. This is where I want to show my resolve as CPO. We will halve processes using Toyota’s skills and digital and innovative technology. We will eliminate the barriers between development and production to provide new mobility quickly. We will also work to resolve issues at the foundation of monozukuri, such as factory carbon neutrality and logistics. We will achieve all these through the power of the genba, where people and technology help each other.

Toyota has been and will continue to be a pioneer in new eras, mass-producing happiness for all by creating a genba with people at the center, where work is done to make someone smile, where gratitude overflows, and people can work with enthusiasm. Let’s change the future of cars with Toyota’s skills!

“Achieving zero, and adding new value beyond it”

As part of efforts to pass our beautiful “³Ô¹ÏÍøÕ¾ Planet” to the next generation, Toyota has identified and is helping to solve issues faced by individuals and overall society, which Toyota calls “Achieving Zero,” hoping to help reduce the negative impacts caused by these issues to people and the environment to zero. Additionally, Toyota is also looking “Beyond Zero” to create and provide greater value by continuing to diligently seek ways to improve lives and society for the future.

- About Beyond Zero

Toyota Motor Corporation works to develop and manufacture innovative, safe and high-quality products and services that create happiness by providing mobility for all. We believe that true achievement comes from supporting our customers, partners, employees, and the communities in which we operate. Since our founding over 80 years ago in 1937, we have applied our Guiding Principles in pursuit of a safer, greener and more inclusive society. Today, as we transform into a mobility company developing connected, automated, shared and electrified technologies, we also remain true to our Guiding Principles and many of the United Nations’ Sustainable Development Goals to help realize an ever-better world, where everyone is free to move.

- SDGs Initiatives