Using neutron imaging techniques at ANSTO, researchers from have gained a better understanding of how corrosion forms and spreads through concrete that is commonly used in sewer pipes.

“The monitoring and mitigation of corrosion in concrete sewer pipes is a significant cost to water utilities around the world that amounts to millions of dollars a year,” said Dr Shima Taheri, a postdoctoral researcher at Macquarie University, who led the study.

With or without reinforcement, corrosion in concrete advances to a point where the concrete has lost its strength, and the damaged area must be replaced immediately to preserve the structure.

The acidic environment in sewer pipes causes corrosion to develop in a complex process.

Engineers monitor concrete for signs of cracks or stress, typically through inspection. Core sampling is used to determine the consistency of the in-service concrete and to detect the signs and depth of corrosion attack.

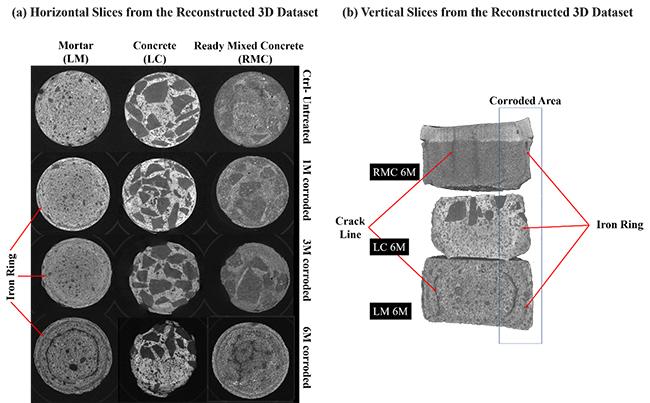

Reconstructed 3D neutron tomography (NT) datasets of specimens (a) uncorroded and immersed in acid bath for 1M, 3M and 6M; (b) corresponding vertical slices of 6M corroded samples (M: month)

Dr Taheri and her associates have shown that non-destructive neutron imaging, coupled with computer modelling, can be used to detect and locate the extent of corrosion early to facilitate timely corrective action.

The research team was assisted by Dingo senior instrument scientist Dr Joseph Bevitt at ANSTO’s .

The team analysed the formation of iron and monitored its movement in unreinforced concrete as part of the corrosion process in a study to be published in the Journal of Construction and Building Materials.

The work has highlighted how the formation of iron-rich zones and their movement contribute to the progression of corrosion and its severity.

“The presence of iron-rich areas could be used as a tool for estimating the remaining useful service life of a concrete structure, particularly a sewer pipeline,” said Dr Taheri.

The was used to non-destructively analyse the internal structure of concrete samples (image above).

The technique can penetrate dense, solid materials, such as concrete.

It can be used to create two- and three-dimensional images of a material, that are generally not observable by other methods.

The researchers carried out experiments using sulphuric acid to accelerate corrosion on laboratory-made concrete samples without iron reinforcements (rebar).

“It revealed the distribution of aggregates and sands within the cement paste, the presence of cracks, voids, and, more importantly, the presence and thickness of the corrosion front,” explained Dr Taheri.

On the tomographic images, the iron-rich zone is a layer of a distinctive golden brownish colour, which indicates an increased amount of iron.

“We observed that the formation of an iron ring and its enrichment occurs at the border of the corrosion front and a transition zone,” she said

The iron ring appeared to be a uniformly distributed zone within the transition zone between areas showing an advanced level of corrosion and areas showing initial stages of corrosion.

Only a few previous studies have reported the presence of an increased amount of iron in corroded areas of concrete. All of those reports concerned samples containing an iron rebar.

“Our samples, however, did not contain an iron rebar nor was the experiment performed under the influence of an iron-oxidising bacteria. The formation of an iron-rich zone has a direct link with the severity of corrosion in concrete, regardless of the presence or absence of metallic rebar or microbial activity,” explained Dr Taheri.

This research won one of ANSTO’s Neutron and Deuteration Impact Awards, demonstrating its relevance to Advanced Manaufacturing and Soil and Water, two of Australia’s research priorities.