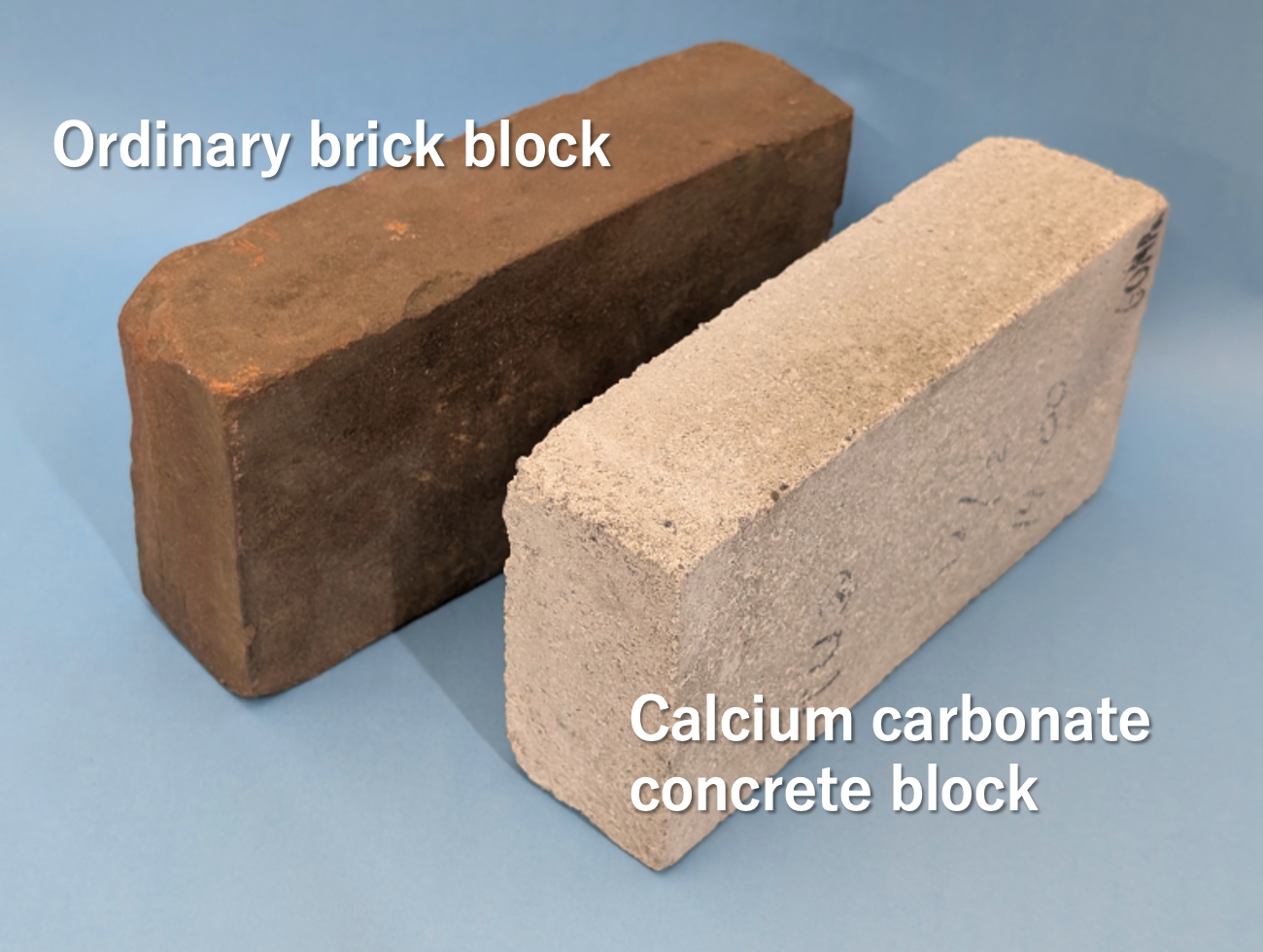

Researchers led by a team at the University of Tokyo have turned concrete from a demolished school building and carbon dioxide (CO2) from the air into new blocks strong enough to build a house with. The process involved grinding the old concrete into powder, reacting it with CO2 from the air, pressurizing it in layers in a mold and finally heating it to form the new block. Instead of making buildings from new concrete only, this technique could offer a way to recycle old materials while also trapping carbon dioxide in the process. The blocks could theoretically be remade again and again, through the same process.

A few years ago, researchers developed , which had the potential to reduce greenhouse gases and reuse waste from the construction industry.

The project was named C4S, which stands for Calcium Carbonate Circulation System for Construction, and led by Professor Takafumi Noguchi, as project manager, with Professor Ippei Maruyama leading on material development. Both researchers are from the Department of Architecture at the University of Tokyo. Together with a team they developed a method to combine old concrete with carbon dioxide, taken from the air or industrial exhaust, to create a new, durable material called calcium carbonate concrete. However, the resulting blocks were only a few centimeters long.

Now, they have taken this technology to the next level.

“We can make calcium carbonate concrete bricks large and strong enough to build regular houses and pavements,” said Maruyama. “These blocks can theoretically be used semipermanently through repeated crushing and remaking, a process which requires relatively low energy consumption. Now, concrete in old buildings can be thought of as a kind of urban mine for creating new buildings.”

Limestone is a key ingredient in Portland cement, which is typically used to make concrete. The rock provides durability and strength, while improving workability. However, limestone reserves are limited, and in some countries more than others, such as Japan. So attention is switching from creating new materials to maintaining and reusing what is already available.

“We are trying to develop systems that can contribute to a circular economy and carbon neutrality. In Japan, the current demand for construction material is less than in the past, so it is a good time to develop a new type of construction business, while also improving our understanding of this vital material through our research,” explained Maruyama.

Demolished concrete from a school building was crushed into a fine powder, sieved and then carbonated over three months. Carbonation is usually a slow, natural process which occurs when compounds in concrete, such as portlandite and calcium silicate hydrate, react with CO2 in the air to form calcium carbonate. The researchers performed a sped-up version of this process to recreate the same kind of concrete you would find in older buildings. This was to test that they could still make strong new blocks even from older concrete.

The carbonated powder was then pressurized with a calcium bicarbonate solution and dried. In their previous experiment, the team created calcium carbonate concrete by pouring a bicarbonate solution through carbonated concrete powder and heating it. In this updated version, as well as heating the material, the team built the concrete up in layers in a mold, which compacted it under pressure. They found this enhanced the strength of the blocks.

“As part of the C4S project, we intend to construct a real two-story house by 2030,” said Maruyama. “Over the next few years, we also plan to move to a pilot plant, where we can improve production efficiency and industrial application, and work on creating much larger building elements, as we move towards making this material commercially available.”